How To Reduce Waiting Times During Peak Service

- Bistro Trailers

- 5 days ago

- 6 min read

Long queues can feel like a success. They signal demand and popularity. But for many food trailer owners, they also bring stress, slower output, and customers walking away before ordering. It’s easy to assume that peak service chaos is simply part of the job.

The good news is that most waiting-time issues aren’t caused by limited space or lack of demand. They’re usually the result of small workflow gaps that can be fixed. A few smart adjustments can dramatically improve speed without lowering quality.

In this guide, we’ll look at practical ways to reduce waiting times during busy periods, from prep batching and menu simplification to layout tweaks and clearer team roles, so your trailer runs smoother during critical moments.

Why Speed of Service Hits Your Business

Speed isn’t just about keeping customers happy. It directly affects how much revenue your food trailer can generate during peak hours. When service slows down, output drops. And when output drops, you leave money on the table.

Many operators focus on food quality, which is essential, but underestimate how much time impacts profitability. Saving just one or two minutes per order can transform a busy lunch rush.

Small Time Savings, Big Revenue Impact

Consider this simplified example during a two-hour peak period with an average spend of £10 per customer:

Average Wait Time | Customers Served Per Hour | Revenue Per Hour |

8 minutes | 7 | £70 |

6 minutes | 10 | £100 |

4 minutes | 15 | £150 |

The difference between eight minutes and four minutes might not sound dramatic. Over two peak hours, however, that shift could mean hundreds of pounds in additional revenue.

Speed also affects perception. A queue that moves steadily feels shorter than one that stalls. Even if the total wait time is similar, visible progress reassures customers and keeps them committed to ordering.

Fix Your Workflow Before Blaming Demand

When service slows down, it’s tempting to assume you simply need more staff or a bigger trailer. In reality, most peak-time delays come from workflow issues rather than capacity limits.

Before making big changes, take a close look at what actually happens during a rush. Where does the line stop moving? Is it during ordering, payment, cooking, or handover? Identifying the exact bottleneck is far more effective than adding pressure everywhere.

Map the Journey From Order to Handover

A simple way to visualise it:

Order → Payment → Cooking → Assembly → Handover

Now ask:

Which stage takes the longest?

Where do staff cross paths?

When does communication break down?

Even small friction points can create long delays.

Clear Roles Improve Flow

In many trailers, everyone does everything. That feels flexible, but during peak periods it often causes confusion and repeated movements. A structured setup is usually faster.

For example:

One person focuses on taking orders and payment

One manages cooking

One assembles and hands over

Workflow Comparison

Unstructured Setup | Structured Setup |

Staff multitask constantly | Defined responsibilities |

Frequent interruptions | Clear task focus |

Slower output | Predictable, steady flow |

Batch Prep Is Your Secret Weapon

During peak service, cooking one order at a time rarely works. It feels controlled, but it slows everything down. Batch prep allows you to stay ahead of demand instead of constantly reacting to it.

The key is preparation before the rush begins. Ingredients that are washed, sliced, portioned, and ready to go reduce decision time and movement during service. Even shaving off a few seconds per order makes a noticeable difference once the queue builds.

Prep Before the Peak

Think about what can be done in advance without compromising freshness.

Pre-slice vegetables

Pre-portion sauces into bottles

Toast buns in small batches

Pre-cook certain components where safe and appropriate

Cook in Controlled Batches

Instead of placing one burger on the grill at a time, anticipate demand patterns. If you know lunch peaks at 12:30, begin cooking slightly ahead.

Batch Cooking Comparison

Method | Time to Serve 10 Orders |

Cook individually | 15 minutes |

Controlled batching | 8–10 minutes |

Use Safe Holding Techniques

Hot holding cabinets or insulated trays can help maintain quality while giving you breathing space. The goal is balance. Prepare enough to stay ahead, but not so much that waste increases.

Simplify the Menu During Peak Hours

A long menu looks impressive. It suggests variety and flexibility. During peak service, however, it often becomes the main cause of delay.

Every additional option adds decision time for the customer and preparation time for your team. Multiply that by twenty or thirty orders in a short window, and the impact becomes clear.

Fewer Choices, Faster Decisions

Customers under time pressure prefer clarity. When they can understand your menu in seconds, they order with confidence. When they hesitate, the queue slows.

Reducing your peak-time menu does not mean reducing quality. It means focusing on your strongest sellers.

Example: Full Menu vs Peak Menu

Full Menu | Peak Menu |

12 mains | 5 best sellers |

8 sides | 3 top sides |

Custom build options | Standard combinations only |

Multiple sauces | Pre-set options |

Limit Customisation

Build-your-own dishes sound attractive, but they slow down production and increase mistakes during busy periods. Standardised combinations are faster to assemble and easier to train staff on.

You can still offer full flexibility during quieter hours. The difference is being intentional about when complexity is allowed.

Speed Up Ordering and Payment

Even if your kitchen runs efficiently, delays at the front can undo the progress. Ordering and payment often create invisible bottlenecks that stretch queues longer than necessary.

The first step is clarity. When customers can see the menu clearly and understand pricing without asking questions, ordering becomes quicker and more confident. Large text, short item names, and visible prices reduce hesitation.

Make Payment Frictionless

Payment time adds up. Thirty extra seconds per order during a busy hour can significantly reduce output.

Payment Time Comparison

Payment Method | Average Time |

Cash | 40–60 seconds |

Contactless card | 10–15 seconds |

Pre-set combo on POS | Under 10 seconds |

Separate Ordering and Collection

If space allows, separating the order point from the collection point prevents crowding and confusion. Customers waiting for food are not blocking those trying to pay.

Layout Design That Supports Speed

Sometimes waiting times have less to do with staff performance and more to do with physical layout. If team members are constantly stepping around each other or reaching across workspaces, small delays quickly build up.

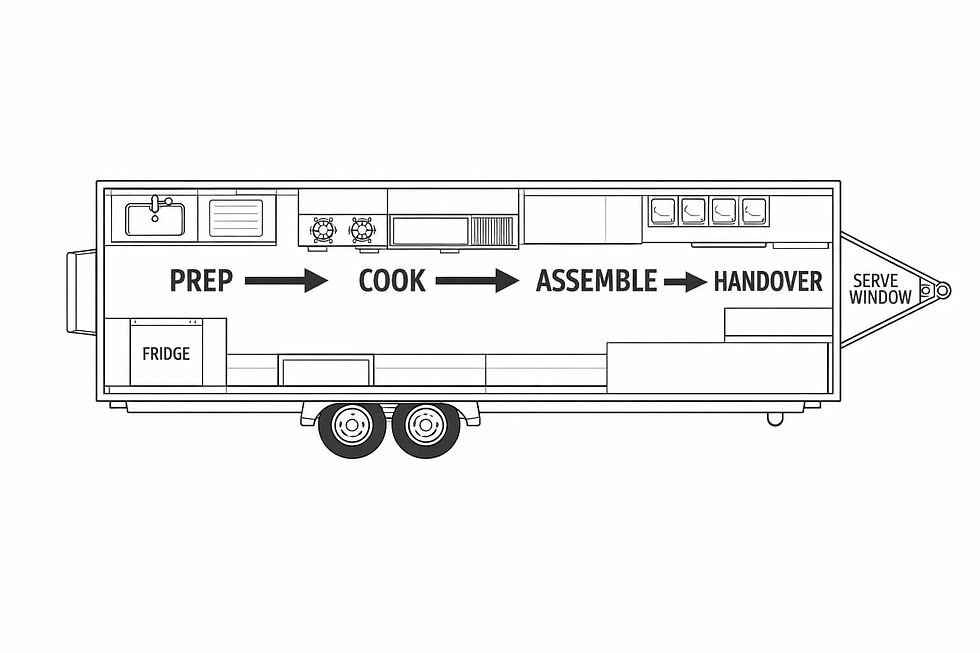

An efficient trailer layout supports movement in one direction. Ingredients flow from storage to prep to cooking to assembly without unnecessary crossing. When staff paths overlap, friction increases.

One-Way Workflow

A simple principle works well in compact kitchens:

Prep → Cook → Assemble → Handover

Separate Order and Collection Points

If customers collecting food stand in the same area as those ordering, congestion forms. Even a small shift in positioning can reduce crowding.

Layout Efficiency Comparison

Layout Type | Impact on Service |

Shared prep and plating space | Slower, more interruptions |

Dedicated assembly zone | Faster, clearer workflow |

Staff crossing paths | Higher error rate |

Linear workflow | Steady, predictable output |

Equipment Placement Optimisation

Place high-use equipment within easy reach of the person assigned to it. The grill should sit near the prep station. The plating area should be clear and unobstructed. The POS should be positioned to avoid blocking movement.

Manage Customer Expectations

Even when service is efficient, perception still matters. A five-minute wait can feel long if nothing appears to be happening. The same five minutes can feel reasonable if customers see steady progress.

Movement reassures people. If they can see food being cooked, plated, and handed over, they are more likely to stay in line. A closed or cluttered service area creates uncertainty.

Make the Process Visible

Open prep areas, visible grills, and clear handover points create transparency. Customers understand that work is happening, even if they’re waiting.

You can also support this with small visual cues:

Clear signage directing where to order and where to collect

Number systems for order collection

Simple statements such as “Freshly prepared, approx. 5 minutes”

Keep the Queue Organised

An unclear queue causes frustration. Barriers, rope lines, or clear floor markers help maintain flow. When people know exactly where to stand and what to expect, stress reduces.

Managing expectations doesn’t shorten actual cooking time, but it can dramatically improve the experience. Customers who feel informed are more patient, even during peak service.

Smoother Service, Stronger Revenue

Reducing waiting times during peak service isn’t about rushing or cutting corners. It’s about building a system that supports speed naturally. When workflow is clear, prep is batched, menus are streamlined, and layout supports movement, queues move steadily instead of stalling.

Small improvements compound quickly. Saving a minute per order during a busy lunch rush can significantly increase hourly revenue without raising prices or adding more space.

If you’re planning a new setup or refining your current one, at Bistro Trailers we design food trailers with efficient layouts that support faster service from day one.

Key Takeaways

Speed of service directly impacts peak-hour revenue

Identify workflow bottlenecks before adding staff

Batch prep helps you stay ahead of demand

Simplified menus reduce decision time and errors

Contactless payment speeds up transactions

Smart layout design improves throughput

Clear communication improves customer patience